The Future of Building Design is Beyond Digital – It’s in Digital Twin BIM Modelling

‘Digital twins’ are dynamic virtual building replicas which can use real-time data from Internet of Things-powered tools to mirror and analyse construction projects. Petruf Consulting Structural Engineers are making use of this next-generation technology now to deliver better predictive maintenance and optimised efficiency.

Imagine if, at the design stage of a project, you could map out a full build, start to finish, and predict drawing clashes and onsite delays before commencing works. ‘Digital twins’ are that reality, using information from a variety of sources to assist in the design and construction of buildings, and ongoing maintenance and development.

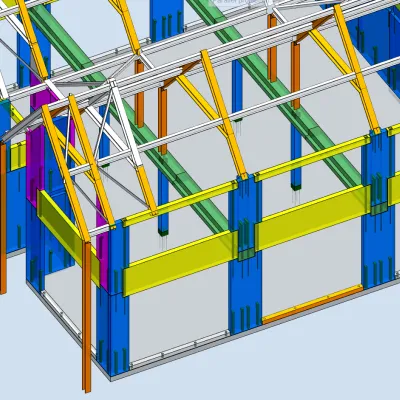

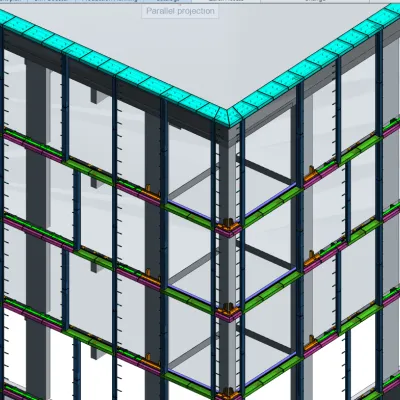

Digital twins are made possible by linking Building Information Modelling (BIM) software used to map technical drawings in a digital environment with interconnected sensory technologies on the physical site actively monitoring and relaying data. This delivers a solution optimised for construction efficiency and stakeholder collaboration.

This technology is a shared reference point for Architects, manufacturers, and contractors. Structural intent, connection details, and build sequencing are transparent, reducing the risk of misinterpretation, shortening feedback loops, and supporting decision-making from concept through fabrication and installation.

Digital twins also allow designers to identify structural, tolerance, and sequencing risks before work begins. Compliance checks, coordinated details, and design responsibility are also embedded in the design model. This supplements construction professionals’ ability to conduct regular building control compliance checks, improves design traceability, and reduces the likelihood of unsafe site conditions.

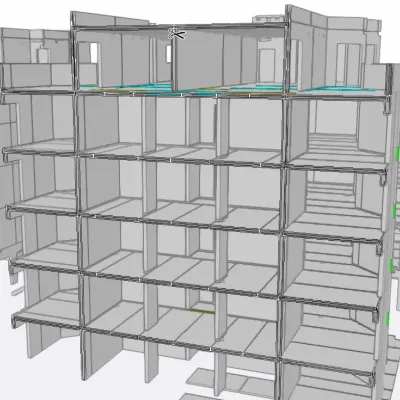

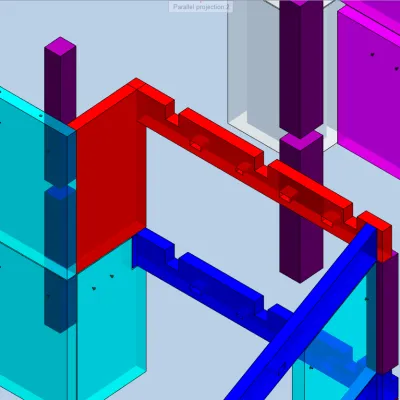

As an example: by testing the fitting of precast concrete slabs in a digital simulation first, designers can precision engineer the slabs to ensure smooth installation onsite. This negates the time that may otherwise be spent on remedial fixes to the slabs onsite or the need for products to be returned to the prefabrication facility for re-casting. With digital twin workflows you can also monitor project performance and delivery in real-time, allowing construction schedules to be planned in advance or adjusted on the fly.

Petruf Consulting Structural Engineers is an experienced structural engineering design firm offering cost-effective precast concrete solutions for faster and higher quality building. Petruf Engineers has a range of experience, in Ireland and abroad, on developments with commercial, educational, residential, and industrial applications.

Frank Petruf, Managing Director at Petruf Engineers, talked about the firm’s modern design approach and how this approach is enabled by industry leading software.

“For Modern Methods of Construction (MMC) projects, using a digital twin as a coordinated, data-rich structural program means integrating structural geometry, connections, tolerances, and sequencing into a single model for design coordination, off-site manufacture, and onsite installation.”

Managing Director at Petruf Engineers

How has the business excelled in delivering builds faster and more effectively? By ensuring its engineers are at the cutting-edge of industry developments and making Continuing Professional Development (CPD) a core part of life at Petruf Engineers.

Frank says that while the firm looks for traditionally trained civil and structural engineers, digital skills (including BIM and digital model-based coordination) are key accompaniments to the engineering fundamentals. He also emphasised that, perhaps counter-intuitively, that “the focus is not software-led design, but using digital tools to support better engineering decisions and constructability.” To achieve this, the company undertakes regular upskilling to support the use of digital engineering tools.

“Our team undertakes ongoing CPD in BIM coordination, precast concrete design, and Irish regulatory requirements. This includes internal knowledge sharing, manufacturer-led workshops, and project-based learning. Upskilling is also directly linked to live projects to ensure tools are applied practically.”

Managing Director at Petruf Engineers

Engineers are supported in deepening their own technical and digital capability. This ensures alignment with Ireland’s digital construction roadmap while maintaining professional accountability for real-world delivery outcomes on key developments.

A recent residential development Petruf Engineers was involved with is on an apartment block scheme in Shankill, Co. Dublin.

The firm was contracted to provide coordinated structural design models of precast concrete components. Using a digital twin of the physical buildings, Petruf Engineers helped the main contractor to reduce design clashes and the need for rework before tender. This enabled earlier engagement of the precast concrete manufacturer, a smoother approval process, and faster onsite installation overall.

The result? Far fewer formal Requests for Information, reduced modifications at all stages of the build, and greater programme certainty when compared to traditional processes for construction when using 2D technical design coordination only.

A key person on this project, with his coordination skills and commitment to meeting deadlines, was Jaroslav Vomacka, Senior Structural Technician at Petruf Engineers.

Jaroslav is a qualified Civil Engineer with a Master's degree and more than eight years of experience in structural detailing, 3D modelling, and digital drafting and coordination. He has specialised in BIM over the years through practical project delivery using Allplan and AutoCAD, all while working closely with architects, engineers, and manufacturers.

First coming to Ireland in 2019, Jaroslav joined Petruf Engineers in 2023 because he had the opportunity to progress in his design career path from a BIM Coordinator role to his current senior position. Part of this change was the desire to continue his upskilling.

“I have continuously upskilled while in my role through advanced detailing work, coordination roles, and adapting workflows for precast concrete projects delivery, focusing on accuracy, data consistency, and coordination efficiency.”

Senior Structural Technician at Petruf Engineers

This process of ongoing upskilling is only set to continue as Jaroslav continues to refine his understanding of MMC and digital twin workflows.

“I plan to deepen my expertise in precast concrete structure 3D modelling, digital coordination for automated production, and data-driven workflows. My focus is on improving how digital models support manufacturing, sequencing, and onsite execution, ensuring digital construction delivers tangible value.”

Senior Structural Technician at Petruf Engineers

The Shankill project is just one example of Jaroslav’s use of detailed construction drawings and coordinated 3D BIM modelling to deliver construction excellence.

Petruf Engineers has also been involved in the notable Horgan’s Quay development in city centre of Cork. Working with the client, BAM Ireland, a total of 273 precast concrete elements were installed in less than three weeks, greatly speeding up project delivery.

Looking ahead, we asked Frank how he saw digital twin technology continuing to evolve in Ireland and what he thinks are the opportunities for scaling MMC adoption? His response indicates a future where efficient project delivery is based on digital twins.

“We see digital twins becoming a baseline requirement for scalable MMC residential, hospitality, educational, healthcare and commercial projects delivery. As planning, building control management systems, and manufacturer workflows mature, digitally coordinated designs will enable faster approvals, more predictable costs, and repeatable production. This is critical for delivering higher volumes of building without increasing onsite risk or labour demand.”

Managing Director at Petruf Engineers