Rebar Revolution: Automating Steel Reinforcement Manufacturing

How Midland Steel is using automation in its new steel manufacturing facility to deliver innovation projects constantly driving Modern Methods of Construction.

Midland Steel has led in advanced manufacturing techniques for the construction industry for 15+ years. With the recent opening of a new smart factory in Portlaoise, this lead has now been superpowered by Modern Methods of Construction (MMC).

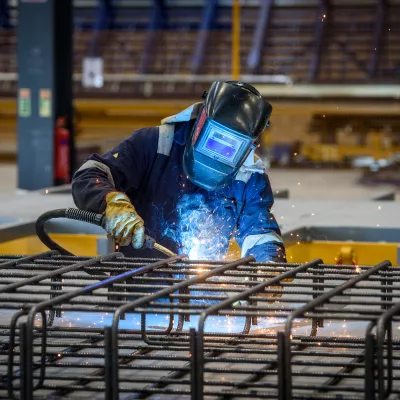

The company has long been known for its FasterFix solution. However, even with this near decade-old innovation, fixing steel bar reinforcement in construction remains the most dangerous and time-consuming activity on a building site. Midland Steel have the solution to revolutionise the bar reinforcement industry.

Midland Steel’s new smart facility in Portlaoise

Midland Steel’s new smart facility in Portlaoise automates the assembly of these products off-site. An immediate benefit? Improved safety onsite, according to Tony Woods, Managing Director of Midland Steel and Chair of the Skillnet MMC Accelerate Working Group.

“The most dangerous activity onsite is steel fixing; we’re ... moving it to a controlled environment and then delivering [the products] with far fewer people required [at the construction site], making the process much safer.”

This process is also significantly more efficient, driving down the timeline of builds.

We are offering ... the ability to get foundations built and above ground 75% faster.

Managing Director of Midland Steel and Chair of the Skillnet MMC Accelerate Working Group

Another benefit is addressing workforce shortage in the construction sector.

More than 60 jobs are being created with the opening of the fully automated steel fabrication facility in Co Laois. Minister for Enterprise, Trade and Employment Peter Burke officially opened the new facility at Midland Steel in Portlaoise on the 7 March 2025.

Current roles in the facility include highly qualified people, covering Building Information Modelling detailers, civil engineers, cost estimators, surveyors, robotic technicians and steel reinforcement placers as well as a range of administrative and management positions.

These specialised roles offer places for a highly trained young workforce to deliver on the innovation projects constantly driving modern methods of construction.

If we don’t move to automation, to give the youth of today the opportunity to apply their skills and take on the roles for which they’re destined, I believe the industry has a major problem with attracting people to become steel fixers for the future. Young people want jobs that are automated and digital. We are now providing that.

Managing Director of Midland Steel and Chair of the Skillnet MMC Accelerate Working Group

Midland Steel’s new smart factory, in automating the time-consuming and dangerous assembly of foundations products offsite, gives their skilled workers (delivering on the principles of MMC) their own foundation to excel.

They’re an integral part of our business and always will be. Robots and AI will never replace people.

Managing Director of Midland Steel and Chair of the Skillnet MMC Accelerate Working Group

And this is just the beginning. With the Portlaoise factory up and running, Midland Steel will look ahead to similar improvements at UK and Scandinavian sites too.