Accelerating Off-Site Construction with Kit of Parts and MMC

Construction businesses lose time and money on product testing after design, impacting projects on the ground. Digitising the ‘kit of parts’ for prefabricated assemblies and modular units can help companies get started on building faster.

The design phase of any construction project is vital to ensuring the finished structure is built optimally. Any changes to sketches after first contact with the real world traditionally required extensive re-drawing of plans, at a cost of hundreds of hours in productivity.

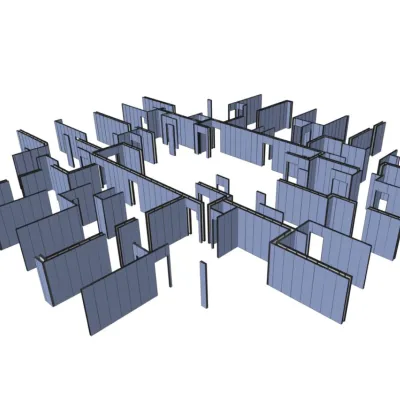

Digital design solutions enable companies to test parts of prefabricated units before they are put together, to optimise the design of individual components within a structure. Creating a stock kit of parts applicable to different projects for repeatability at scale is a core principle of Modern Methods of Construction (MMC). As well as saving time and money, this reduces waste and the risk of breaches in product compliance.

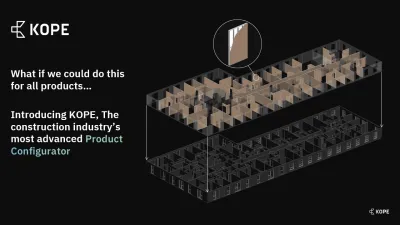

KOPE AI, as a digital design tool, allows users to test real-world, prefabricated products in a virtual model at 21x the rate possible with manual product placement. Companies can estimate costs at any scale while negating the need for time-consuming reworks. KOPE also utilises in-depth insights from products to inform vital project decisions.

KOPE AI, as a digital design tool, allows users to test real-world, prefabricated products in a virtual model at 21x the rate possible with manual product placement. Companies can estimate costs at any scale while negating the need for time-consuming reworks. KOPE also utilises in-depth insights from products to inform vital project decisions.

Data analysts are often good at interpreting data, but not as good at understanding it in context. KOPE's team are construction professionals expert in data analytics, so they fully understand how to help clients with their data.

Construction Solutions Director at KOPE strategic partner Saint Gobain

As a global leader in construction, Saint Gobain knows the importance of using digital technology to address the gap between hypotheticals and realities. KOPE offers Saint Gobain a solution to bridge this gap and take control of each element of a build.

With KOPE, we have the ability to make component data relevant to a customer’s project from a very early stage. This opens a lot of opportunity to add value to a project and deliver in a more productive and sustainable way.

Construction Solutions Director at KOPE strategic partner Saint Gobain

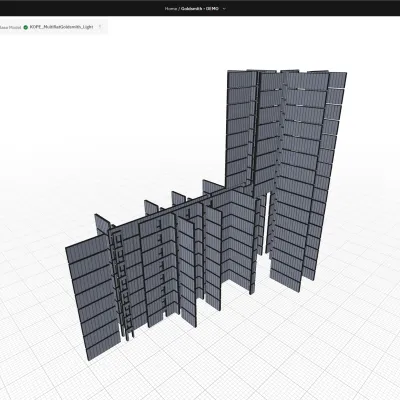

As an example, Saint Gobain used the KOPE software to qualify the suitability of using its proprietary InteWall solution on a large development within a matter of minutes in a controlled digital environment, rather than the weeks it could take in product testing.

InteWall is a pre-panelised internal partition system designed for onsite efficiency. Using KOPE, the Saint Gobain Design team will take a BIM model to produce a layout for the panels and list of components. KOPE will then suggest design modifications to optimise InteWall standardisation for that design concept. Armed with this information, the Design team can optimise and standardise all designs before any prefabrication.

For Paul French, Head of Digital Construction at Saint Gobain, had held numerous technical roles within Saint Gobain before moving into the building information modelling (BIM) side of the multinational construction company. From day one, he saw an obvious strategic need for a digital solution to reduce material waste onsite and limit the number of people hours required for testing of optimum product placement.

Once Paul and Tom identified KOPE as that solution, it was trialled with their Intewall system on several projects, with the digital tool proving fundamental in making the partitions more effective, no matter the project it was deployed on. As Paul French said:

This tool is absolutely vital. Without a viable digital solution to integrate St Gobain products into construction projects, we only have half an offering.

Head of Digital Construction at Saint Gobain

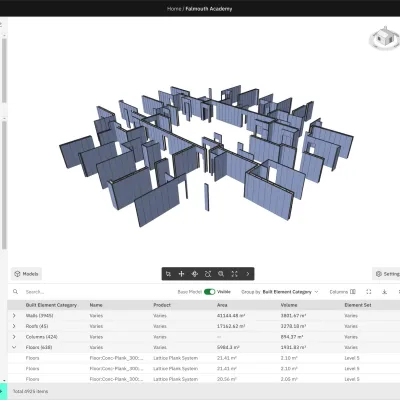

KOPE Customer Success Manager Dayle Zielentino expanded on this. He revealed how the ultimate benefit of digital software giving individuals access to all the necessary data on every component of a build is revealing how each part affects the whole.

KOPE gives teams total transparency of metrics for each unique end user. The software offers a holistic view of each component in the full kit of parts and its place within a project. This enables clients to compare optimal outputs from different project areas and assess whole-system value for better results.

KOPE Customer Success Manager

KOPE claims the value of off-site construction projects globally will reach US$1.2 trillion by 2030. To show the value of off-site construction, companies need control of the build from design onwards. Ensuring each component within a structure’s kit of parts is a natural first step. Experts such as KOPE and Saint Gobain can lead the way.