A Complete NZEB Rapid Build ICF System for More Modern Housing with Thermhouse

Low energy homes, with in terms of carbon output during the build and designed for optimal thermal insulation, are more achievable with Modern Methods of Construction (MMC). Thermohouse, in the heart of Co. Kerry, offers the only complete NZEB ICF system in the country.

A key consideration in modern housing is energy performance. Nearly Zero Energy Building (NZEB) standards apply to all new developments in Ireland, as does Part L of the national building regulations. Both establish requirements related to conserving fuel and energy usage in the construction process. By meeting these standards, building companies can deliver more sustainable developments with a lower consumption of fuel and materials to homeowners that can pay far less in energy bills.

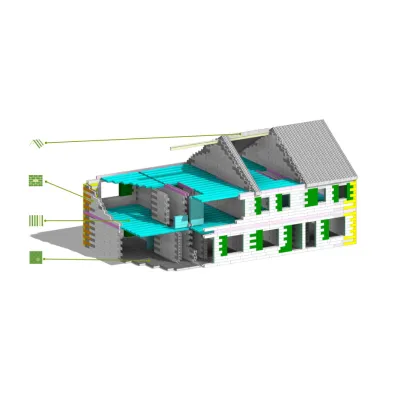

Thermohouse manufactures, supplies, and installs a total ICF building solution that is both NZEB and Part L 2019 compliant. The system, providing the complete structural envelope and featuring superior airtightness, high levels of insulation, and minimal thermal bridging, is comprised of four products interlocked in a complete structure.

The result? High-quality, concrete-build homes, fully enveloped in insulation for warmer and more comfortable home living that are:

- 60% more energy efficient when compared to the average new build.

- 60% faster to build than using traditional methods of construction.

- 60 years-guaranteed in design lifespan for future-proof efficiency.

Michael Cronin, Managing Director of Thermohouse, outlined how this commitment to NZEB building contributes to Thermohouse’s overall aims:

“Our mission at Thermohouse is to supply a building system that is not only sustainable but has the ability to provide comfort, security and a cost-effective solution to the homeowner.”

Managing Director of Thermohouse

The Thermohouse building system is produced at a state-of-the-art manufacturing facility in Killarney, Co. Kerry. Two materials, expanded polystyrene and galvanised steel, are fused through injection moulding and extrusion to form the blocks and panels in the four Thermowall, Thermofloor, Thermoroof, and Thermoboard ICF systems.

Dony Kelly, Technical Manager at Thermohouse, knows in the ins and outs of the company's ICF systems better than anyone.

“I revised the original technical manual for the Thermohouse products to better clarify the Thermohouse complete low-energy building system. This included reviewing, and adding drawings and photographs for visual information. The original technical manual comprised of 26 pages. As an ongoing project and because of changes to building regulations over the years and additional ICF wall forms being introduced to the manufacture line, the manual currently stands at more than 250 pages – it gives a truer understanding of our system.”

Technical Manager at Thermohouse

Dony comes from many generations of builders and started out (working in ink and pen) as a Structural Steel Design Draughtsman with multinational equipment manufacturer Liebherr, before moving into the construction industry. Developing practical skills that would serve him on the ground was a priority, so he taught himself AutoCAD once the technology started to be used more widely. This saved him re-draughting each element of a drawing every time, which made him faster and more efficient.

This approach underpins Dony’s thinking around training in the construction sector:

“Hands-on and being shown is always better for learning. I have travelled nationwide to meet with clients keen to learn how to work with the Thermohouse ICF components and use our various building systems for the first time.”

Technical Manager at Thermohouse

He added that fundamental changes in how we think about the construction of buildings is also important:

“I believe changing mindsets is the hardest hurdle when introducing something different into the marketplace. Every day brings the opportunity to learn something new ... and changing mindset is the biggest opportunity for people to learn new practical skills.”

Technical Manager at Thermohouse

Dony’s technical support on Thermohouse products was advantageous to recent developments at Derreen and Milltown in Killarney, Co. Kerry. In July 2023, Thermohouse started on a low-energy social housing scheme, comprising 28 apartments and 16 bungalows for older persons and people with disability / supported living needs, for Clúid Housing. Clúid Housing selected Thermohouse for this development based on its NZEB compliance, superior sound proofing and airtightness, and substantially reduced building time and need for tools and equipment. These homes, all A2 rated, have recently been completed.

Ihor Kurtiev is a Sustainability Engineer with sister company MC Group, one of Ireland’s largest independent building material suppliers. In his capacity with Thermohouse, Ihor conducts comprehensive energy audits of the manufacturing facility, ensuring that processes remain fully aligned with stringent sustainability standards.

Much like Dony, Ihor came from a different background into being a part of Thermohouse’s off-site manufacturing operation. Studying Alternative Energy in his native Ukraine and running his own green engineering firm, Ihor was hired after arriving in Ireland to increase the sustainability expertise in Thermhouse’s manufacturing site.

“When I came to Ireland, I wanted to learn more about sustainability and the business side of the construction industry to help me find a job in the field. I studied a course in Business Management at Kerry College, completed Asset Management training at the Institute of Asset Management, and obtained my ISO 50001 Lead Auditor certification online through The Knowledge Academy.”

Sustainability Engineer with sister company MC Group

Thermohouse are sharing this multi-trade expertise and the story behind their success in sustainable building with a site tour of their manufacturing facility at Coolcaslagh, Co.Kerry, on Wednesday 3 September 2025. A part of the Skillnet MMC Accelerate series of business support events across Ireland, attendees will get the opportunity to see how Thermohouse ICF is manufactured and hear from regional leaders in MMC.

Conor Hayes, the Irish Concrete Federation’s Head of Sustainability, is one such leader. At the Thermohouse event he will discuss the importance of sustainability in building — “sustainability should be a standard performance metric for projects”— and the place of concrete in the future of Irish construction. With 17+ years’ experience in the building sector, Conor brings a broad view of how “a positive environmental impact with lower carbon output needs to match quality, durability, and functionality” on projects. He also acknowledged the benefits of the business support events:

“The construction industry can be quite disconnected, across the different ways of building and client sectors. We need to better communicate with each other.”

Head of Sustainability, Irish Concrete Federation

Damien Gleeson, Development Specialist at Thermohouse, echoed the importance of these business support events for bringing the construction industry together:

“These business support events are vital to companies like Thermohouse as they give us the exposure to showcase how we manufacture, supply, and build complete energy-efficient building systems that deliver high performance and future-proof housing developments. The event also gives stakeholders in construction the opportunity to see how an Irish company based in Co. Kerry can proactively deliver MMC solutions needed to increase the supply of housing across Ireland. We have the capacity to deliver high volumes of an innovative MMC product and, with an event like this, stakeholders can see how ICF can be a solution for any project in Ireland.”

Development Specialist at Thermohouse

Want to learn how Thermohouse ICF is manufactured and hear from regional leaders in MMC? Register now for the Thermohouse facility visit on Wednesday 3 September.